Throughout history, cast iron has been and continues to be a vital resource in a multitude of industries. Utilized for centuries, cast iron has its origins in ancient China and continues to be a popular material due to its amazing properties and adaptability.

Due to its robustness, the initial uses of cast iron were for the production of tools and weapons. Nevertheless, with the advancement of civilization, its utility grew to encompass architectural components like columns, beams, and decorative embellishments. The Industrial Revolution also accelerated the implementation of cast iron in constructing infrastructure, apparatus, and engines. Due to the exceptional properties and uses of cast iron, it has historical significance and continues to be relevant.

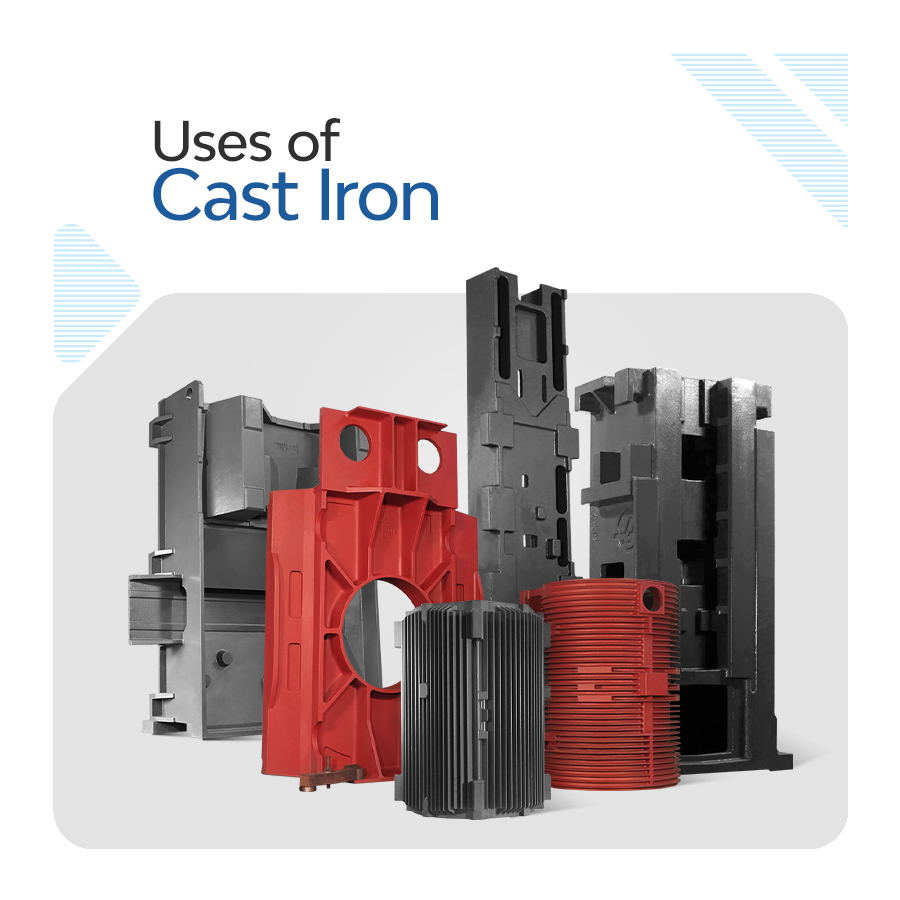

There are countless uses of cast iron in the modern world. Come, let’s explore the popular uses of cast iron.

What are the Uses of Cast Iron?

The remarkable properties of cast iron render it well-suited for a diverse array of applications across numerous industries. The following are some typical uses of cast iron:

Road Making Equipment Casting

Road construction equipment’s structural integrity and operation are dependent upon these castings. Construction commonly involves the utilization of resilient materials like steel and cast iron.

Method: Die Casting or Sand Casting

Uses of Road Making Equipment Casting

Asphalt Pavers

The utilization of road-making equipment castings in asphalt paver construction serves the purpose of providing support and guidance to the paving machine during the asphalt application process on roadways and major thoroughfares.

Road Rollers

Road rollers are imperative components in the road construction process as they consolidate asphalt, gravel, and other substances to guarantee a smooth and long-lasting surface. In this regard, castings assume a critical function in the manufacturing process.

Graders

Castings on graders facilitate the leveling and grading of road surfaces to ensure adequate drainage and safe driving conditions. On construction sites, the functionality and efficacy of graders are dependent on these castings.

Automotive Industry

Materials utilized in the automotive industry vary according to the component in question and its specifications. Worthy of its strength, durability, and resistance to heat, cast iron is a frequently employed material. Due to its resistance to elevated temperatures and substantial pressures, cast iron finds application in a wide array of automotive components.

Method: No Bake Mold Casting

Uses of Cast Iron in Automotive Industry

Engine Blocks

Cast iron finds widespread application in the fabrication of engine blocks owing to its exceptional mechanical integrity and thermal conductivity. Internal combustion engine engine blocks contain the cylinders, pistons, and other vital components.

Braking Systems

Automobile braking systems frequently employ brake components made of cast iron, including discs and drums, owing to their exceptional resistance to wear and heat dissipation. These components are durable and provide dependable stopping power.

Suspension Components

Certain suspension components, including steering knuckles and control arms, are frequently fabricated from cast iron owing to their robustness and capacity to attenuate vibrations and shocks, thereby enhancing the stability and maneuverability of the vehicle.

Windmill Castings

Wind turbine construction components are referred to as “windmill castings.” The market for wind turbine compensators was expected to be worth $2.4 billion in 2022 and is projected to grow to $6.4 billion by 2031. Supporting strength, durability, and precision in severe environmental conditions, they are indispensable to the construction and operation of wind turbines.

Method: No-Bake Sand Mold

Uses of Windmill Castings

Rotor Hub

In the construction of the rotor hub, which serves as the central element to which the rotor blades are affixed, windmill castings are utilized in an indispensable capacity. To enable effective operation, these centers must be able to endure substantial forces and masses while controlling their weight. For this vital component of the turbine, cast iron provides the required durability and strength.

Machine Carriers

An additional crucial utilization is in the production of machine carriers, which function as structural foundations within the nacelle, the enclosure situated atop the wind turbine tower. Machine carriers provide security and support for the generator and other power generation apparatus. Due to its strength and stability in the severe conditions encountered by wind turbines, cast iron is an ideal material for this application.

Connecting Components

Further, windmill castings are utilized in various connecting and sustaining components that are situated throughout the wind turbine assembly. Cast iron materials and the no-bake sand molding process are indispensable for the fabrication of bearing housings, transmission enclosures, and oscillation mechanisms, among other components, which necessitate rigidity and accuracy.

Gearbox Casting

In the field of industrial engineering, specifically in the fabrication of gearbox housings, gearbox casting is a fundamental component. Housings play a critical role in safeguarding and confining the gears and other internal components of gearboxes, which find extensive application in diverse industrial sectors.

Method: Non-Bake Sand Mold

Uses of Gearbox Casting

Industrial Machinery

Gearbox castings are essential constituents of large industrial apparatus, which is prevalent in various sectors including steel factories, paper mills, and cement plants. Critical to the effective operation of industrial machinery, these gearboxes enable precise speed regulation and high torque.

Construction and Mining

Heavy-duty gearboxes find application in construction machinery and mining equipment, such as excavators, transport vehicles, and drilling platforms. Power transmission for excavating, hoisting, and other operations in harsh environments is dependent on these mechanisms.

Wind Turbines

Wind turbines rely heavily on gearbox castings, which are critical elements in the process of converting the blades’ rotational energy into electrical power. In addition to efficiently conveying power to produce electricity, these gearboxes must endure the severe conditions of wind turbine operation.

Electric Motor Housing Casting

Enclosing and safeguarding the internal components of an electric motor is the function of an electric motor housing casting. The castings play a critical role in safeguarding and maintaining the structural integrity of the motor, thereby ensuring its long-lasting operation.

Method: Non-Bake Sand Mold

Uses of Electric Motor Housing Casting

Manufacturing

Heavy machinery, conveyor systems, and other industrial equipment often need large motors to operate. The electric motor housing castings encase and protect these motors, ensuring their dependable operation in industrial environments.

Marine Industry

Ships, boats, and other big maritime machinery rely on powerful propulsion engines to power various onboard systems. Protecting electric motors from the damaging effects of the sea is the job of the castings that surround them.

Renewable Energy

Wind turbines and hydropower plants often use massive motors to produce impressive amounts of electricity. These renewable energy systems rely heavily on enclosure castings for electrical motors to safeguard and preserve the power-generating motors.

Industrial Uses of Cast Iron

Cast Iron’s durability, strength, and adaptability make it useful in many industries.

Pump and Valve Castings

The fabrication of pumps and valves, which regulate fluid in industrial operations, requires castings. Corrosion resistance, machinability, and affordability make cast iron castings popular.

Method: No Bake Sand Mold

Uses of Pump and Valve Castings

Water Treatment

Pump and valve castings manage water and chemical flow in filtration, disinfection, and desalination facilities.

Oil and Gas Industry

Pumps, valves, and pipeline systems use pump and valve castings to extract, process, and transport oil and gas.

Chemical Processing

Pump and valve castings manage corrosive chemical and liquid flow in chemical facilities, guaranteeing safe and efficient manufacture.

Engine Blocks and Cylinder Heads

Internal combustion engine blocks and heads house cylinders, pistons, and valves. Thermal conductivity, durability, and machinability make cast iron ideal for these components.

Method: Sand Casting

Uses of Engine Blocks and Cylinder Heads

Automotive Industry

Automobiles utilize engine blocks and cylinder heads for combustion engines to power and propel vehicles.

Marine Engines

Engine blocks and cylinder heads power boat engines and onboard systems.

Industrial Machinery: Engine blocks and cylinder heads power generators, compressors, and pumps.

Machine Tool Casting

Lathes, milling machines, and grinders employ machine tool castings. These castings support and house machine tool moving components.

Method: No Bake Sand Mold

Uses of Machine Tool Casting

Metalworking Industry

The metalworking industry uses machine tool castings to cut, shape, and polish metal parts and components.

Aerospace Industry

The aerospace industry uses machine tool castings to make precise and high-quality aircraft parts.

Automobile Industry

The automobile industry uses machine tool castings to make engine blocks, gearbox housings, and chassis components with great precision and efficiency.

Earth Moving Equipment Casting

Heavy machinery for earthmoving, mining, and building uses castings. These castings support and house engine blocks, transmission housings, and hydraulic system components.

Method: No Bake Sand Mold

Uses of Earth Moving Equipment Casting

Construction

Earth-moving equipment castings are required for excavation, grading, and site preparation.

Mining

The mining sector employs castings from earthmoving equipment to manufacture haul trucks, loaders, and excavators.

Infrastructure Development

For the construction of roads, bridges, and land, earth-moving equipment castings are necessary.

Heavy Engineering Component

The heavy technical components used in cement, steel, and paper mills are large, robust castings. These castings serve as the housing and support for the gearbox, turbine, and pump housings.

Method: No Bake Sand Mold Without Baking

Uses of Heavy Engineering Component in Casting

Steel Industry

Casting, rolling, and forging heavy engineering components are necessary for the manufacturing and processing of steel.

Paper Industry

Paper mills need heavy engineering components for pulp preparation, paper production, and finishing.

Cement Industry

Heavy engineering components are required for the grinding, mixing, and packaging of cement products.

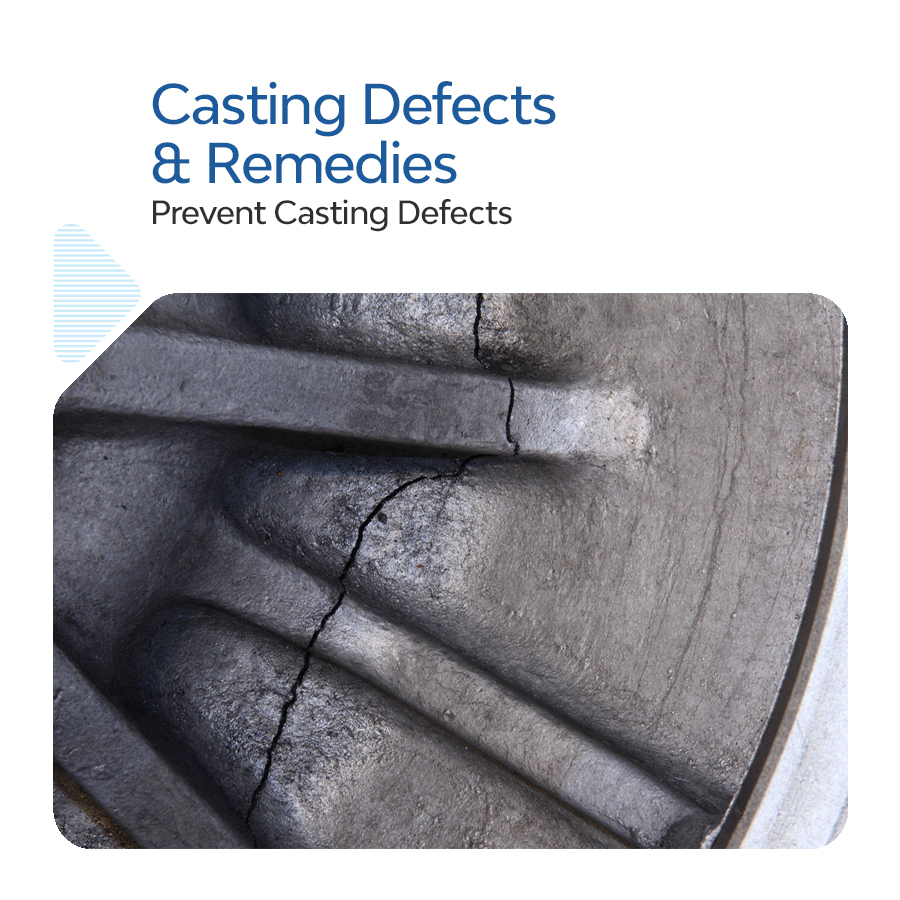

Conclusion

Now that we know the uses of cast iron, remember that Mahadev Precision Cast Iron Foundry provides you with a distinctive advantage. Our rigorous quality control, large manufacturing capacity, and professional technicians and engineers increase this devotion. Our state-of-the-art facilities at Mahadev Precision Cast ensure that our castings are flawless. Our capacity to create 3 tons castings in one separate piece shows we can tackle even the most difficult jobs. With these qualities, we boldly stand out from the competition and create new casting industry standards.

FAQs

What are the useful properties of cast iron?

High strength, exceptional wear resistance, decent machinability, and high thermal conductivity are just a few of cast iron’s advantageous properties.

Is cast iron used for casting?

Cast iron finds widespread application in the casting industry owing to its exceptional flowability into intricate molds and solidification into elaborate forms.

Is cast iron used today?

As an automotive component, cookware material, and construction element, among others, cast iron remains a material of considerable utility despite its antiquity.