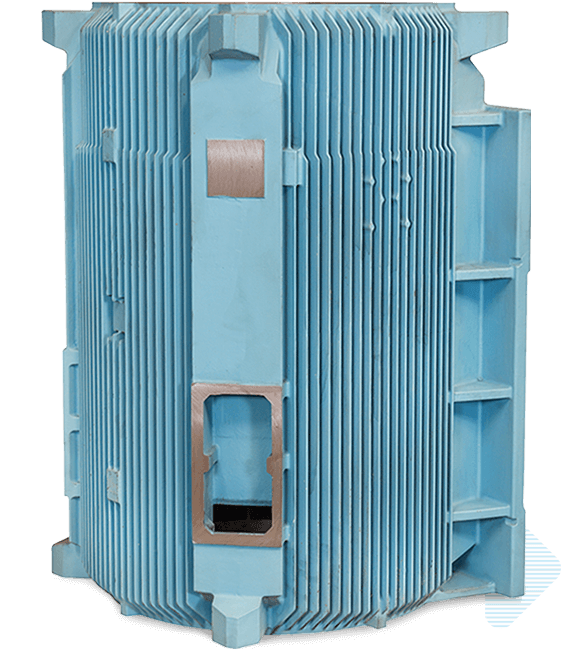

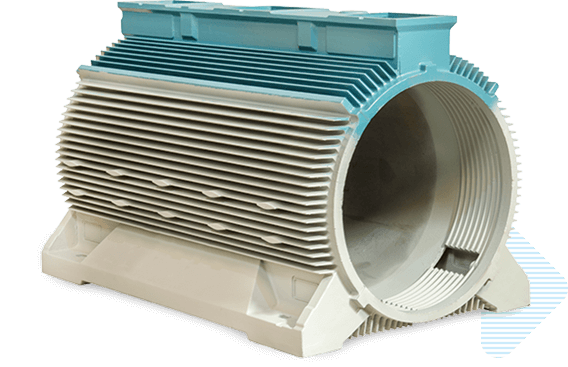

Electric Motor Housing

Casting Manufacturer

The technique of casting sturdy casings to protect the complicated parts of electric motors is known as electric motor housing casting. It entails sculpting molten metal to form sturdy housings that are suited to the particular requirements of every engine.

At Mahadev Precision Pvt. Ltd., we aim toward perfection without quitting. Every housing is carefully and precisely designed, starting with the latest motor body casting procedures. We are the go-to option for a variety of applications because of our dedication to innovation, which guarantees that our castings exceed the highest requirements of performance and durability.

Our electric motor housing castings are proof of the creative potential of people in an innovative environment. We offer more than simply housing—it’s a representation of excellence, dependability, and advancement. You can rely on us to fuel your creations with carefully constructed electric motor housings that surpass your expectations.

Our Diversified Key Elements

Applications of

Electric Motor Housing Casting

Safeguarding and optimizing the performance of electric motors, electric motor housing casting finds essential use in a wide range of sectors. Mahadev Precision Cast, a top electric motor body casting manufacturer meets these diverse requirements.