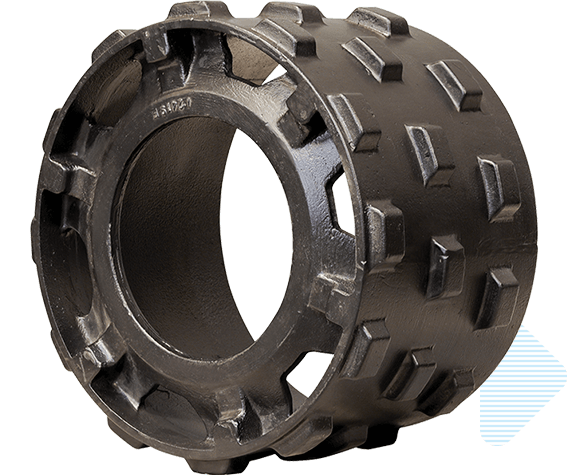

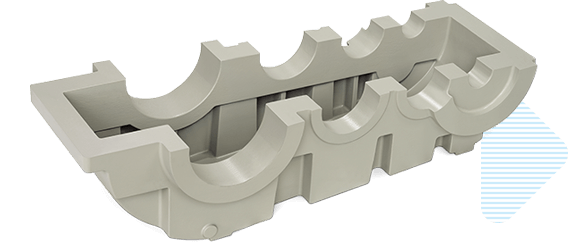

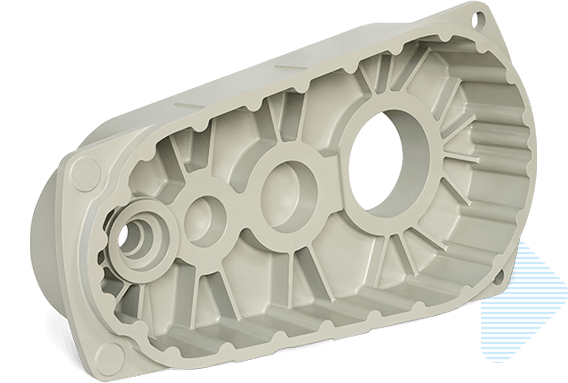

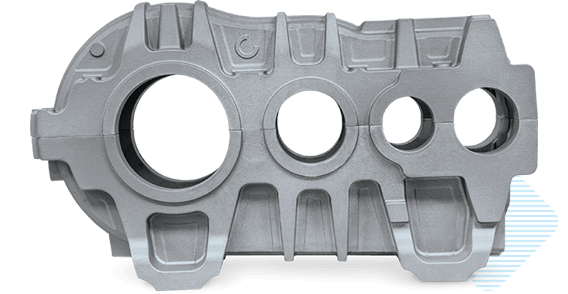

Heavy Engineering Component

Casting Foundry

Molding molten metal into sturdy components that serve as the foundation of heavy equipment is known as heavy engineering component casting. The craftsmanship behind the gearbox castings and towering gearbox housings give life to the mechanical behemoths that propel our planet forward.

It involves more than simply pouring metal into molds; it involves combining innovation and tradition into every part. With decades of combined expertise, our artisans give each casting a laser-like focus on detail and an unrelenting dedication to excellence.

At Mahadev Precision Pvt. Ltd., we push the limits of what is possible in heavy engineering casting by combining state-of-the-art technology and methods. The highest standards of quality and dependability are carefully considered in the construction of each gearbox housing and casting, guaranteeing peak performance even in the most taxing conditions.

Our Diversified Key Elements