Machine Tool

Casting Manufacturer

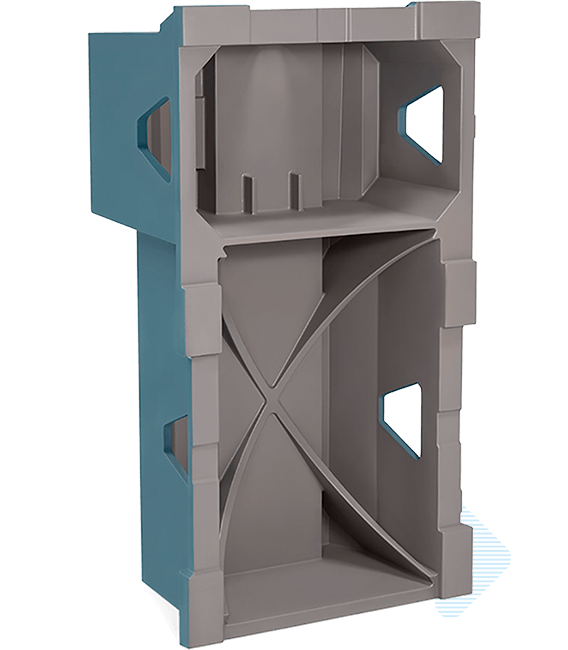

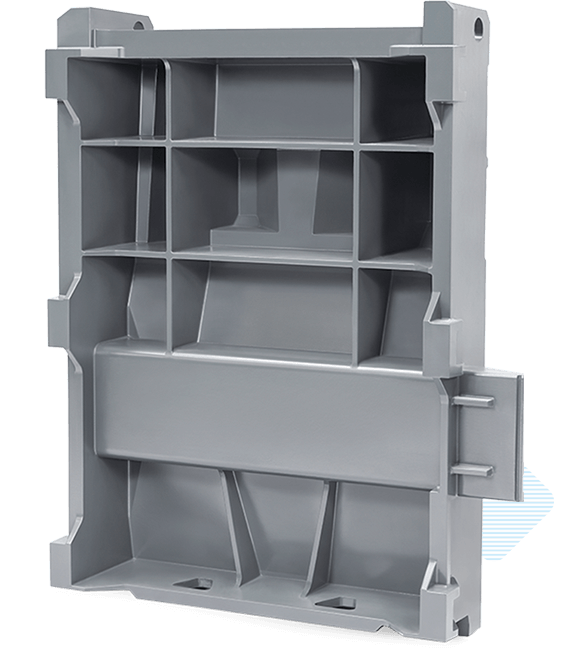

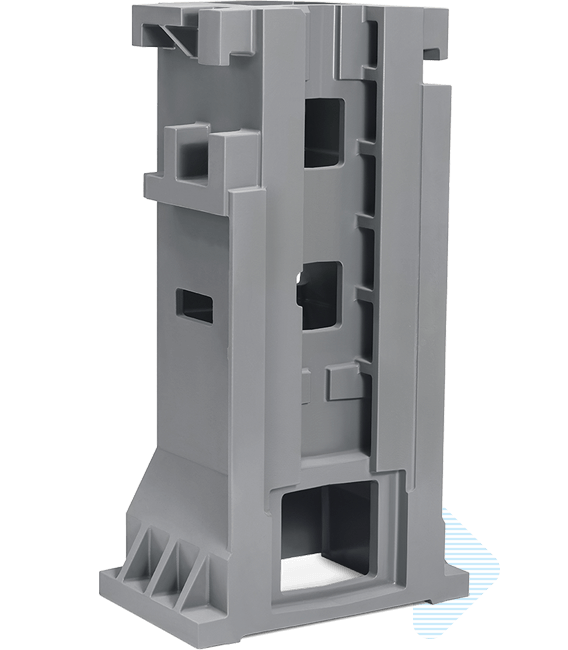

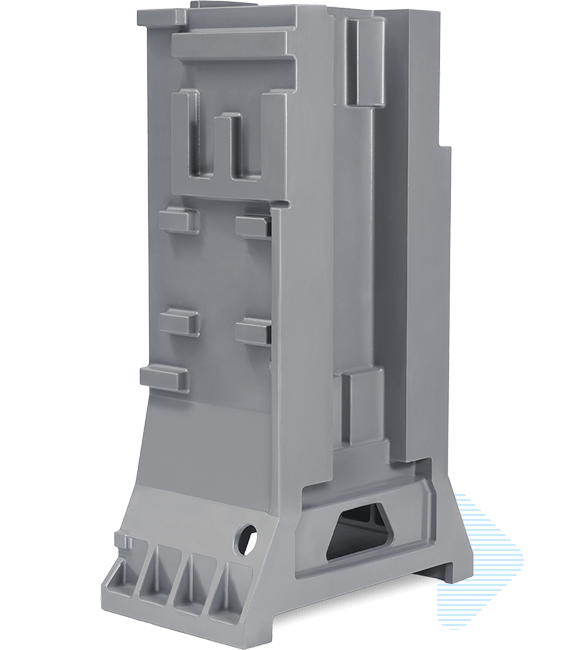

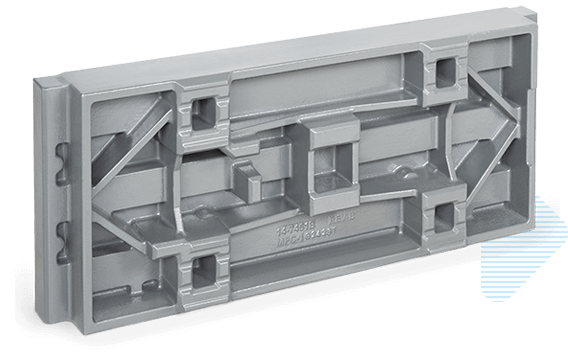

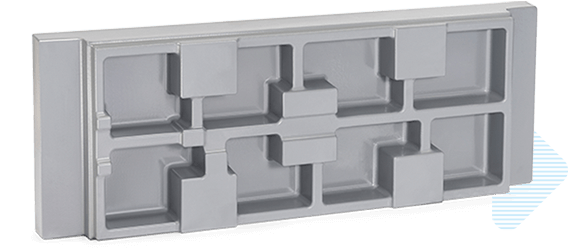

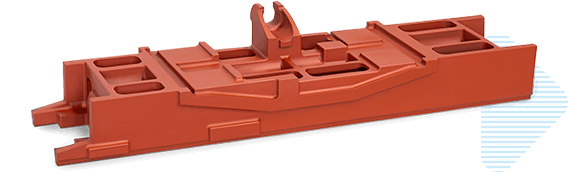

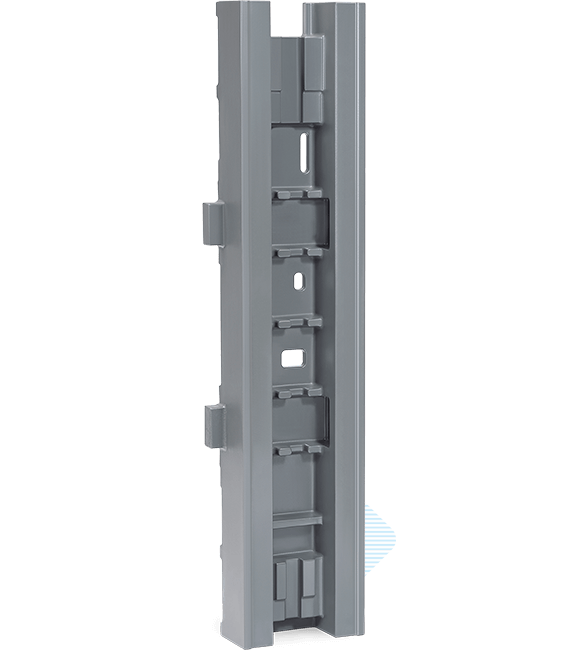

Machine tool casting is an important technique in industrial production because it combines molten metal to create complex parts needed in many industries. In essence, machine tool casting is the art and science of precisely molding metal to meet the complex needs of contemporary industries. This technique is the basis of many mechanical systems, enabling their usefulness and dependability, from the intricacies of fasteners to the intricacy of transmission components.

Mahadev Precision Pvt. Ltd. is unmatched in this sector because of its skillful blending of old-world craftsmanship and modern technical innovations. Mahadev Group guarantees the highest levels of quality and accuracy in each cast component it manufactures by fusing cutting-edge tech with time-honored processes.

Beyond just producing parts, Mahadev Precision Cast fosters long-lasting relationships based on mutual regard, trust, and dependability. Personalized attention and dedication to meeting and surpassing client expectations define our every engagement.

Our Diversified Key Elements

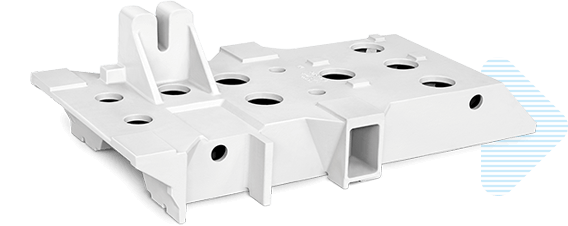

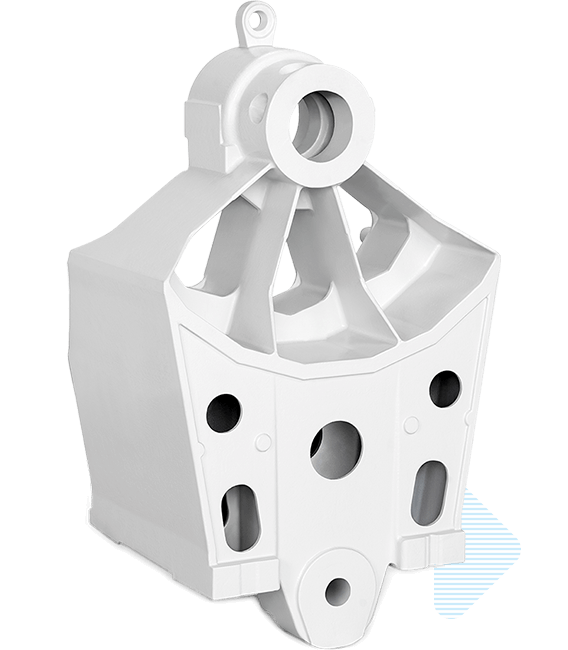

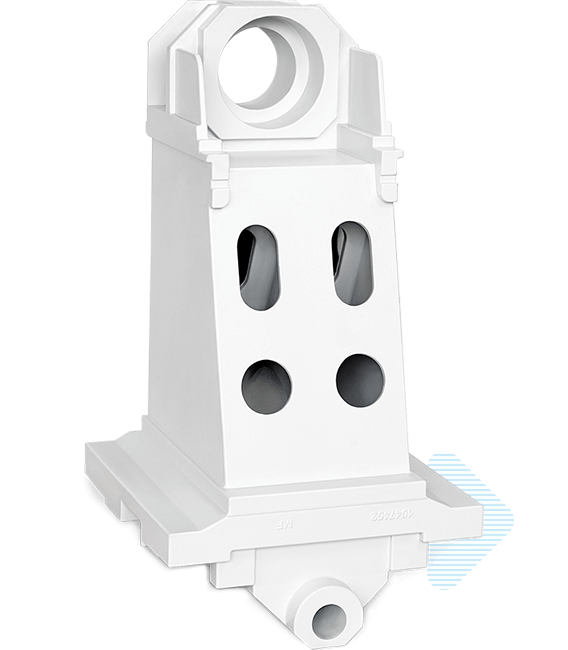

Our Products

Applications of

Machine Tool Casting

Machine tool casting’s flexibility and capacity to create complex, dependable components make it useful in a variety of sectors. Several noteworthy uses include: