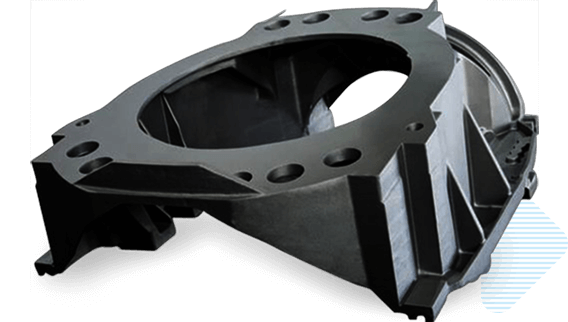

Windmill Casting

Regarding renewable energy, windmills are eminent emblems of sustainability and innovation. But there’s something very important hidden behind these tall structures: wind turbine casting. Mahadev Precision Pvt. Ltd. emerges as the undisputed leader when it comes to being an expert in this field. The process of creating the many parts that comprise these enormous turbines—from the robust tower foundation to the gracefully swaying blades—is known as “windmill casting.”

All of it comes down to combining traditional knowledge with modern innovation. Over many centuries, our artisans have refined their technique to a degree of perfection in casting.

That’s not all, however. We constantly push the envelope of what is feasible; they don’t simply sit back and take it all in. In addition, we make sure that every windmill component is not just of the highest quality but also exceeds industry requirements by using the most recent materials and technology.

Our Diversified Key Elements